Choosing the best diesel engine can be overwhelming, given the variety of options available. Each engine has its own strengths and weaknesses, making it essential to understand the key features that set them apart. This guide aims to simplify your decision-making process.

When selecting a diesel engine, consider reliability, fuel efficiency, maintenance costs, and performance metrics. Each of these factors plays a crucial role in determining which engine will best meet your needs and deliver optimal results.

Diesel Engine Basics

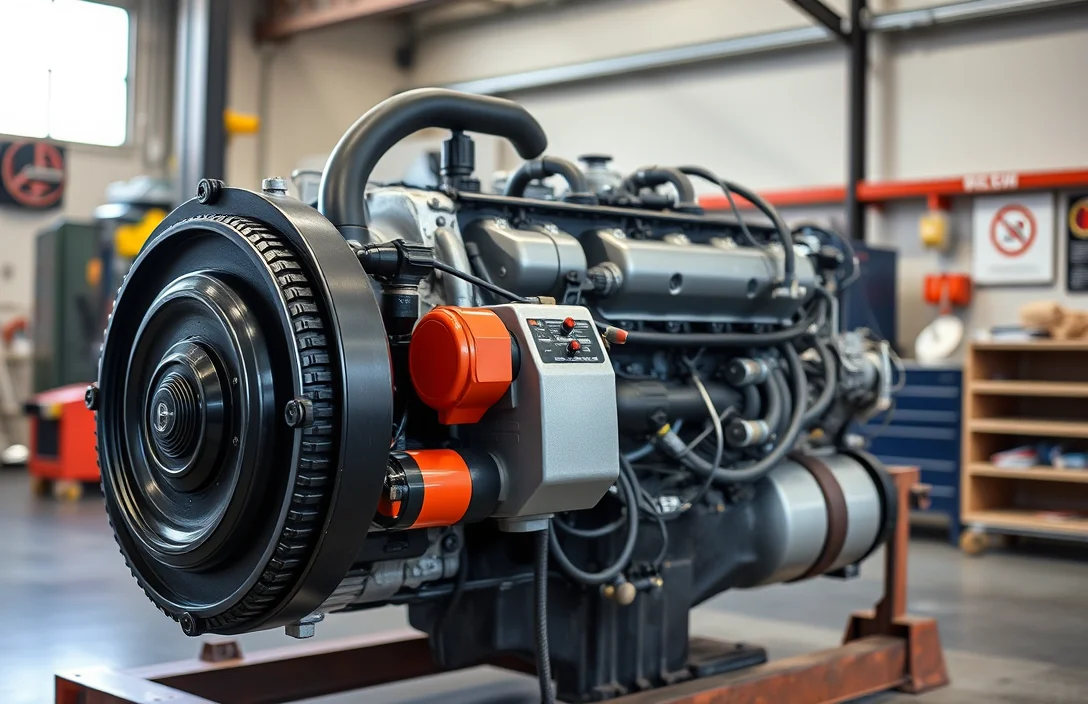

Diesel engines are a type of internal combustion engine that operate using diesel fuel. They are known for their efficiency, durability, and torque characteristics, making them a popular choice in various applications, from automobiles to heavy-duty machinery. Understanding diesel engines is vital when determining which type is best suited for specific needs.

Diesel engines function by compressing air in the cylinder, raising its temperature, and then injecting diesel fuel. This process results in combustion, allowing the engine to generate power. Their higher compression ratio compared to gasoline engines contributes to better fuel efficiency and lower CO2 emissions. Diesel engines are also renowned for their longevity, often outlasting gasoline engines due to their robust construction and lower operating temperatures.

In the automotive industry, diesel engines are prevalent in commercial vehicles, buses, and trucks, where torque and fuel efficiency are paramount. While they may have a higher upfront cost and can produce more nitrogen oxides and particulates than gasoline engines, advancements in technology have led to cleaner, more efficient models. Evaluating the best diesel engine requires considering engine type, application, and regulatory standards.

Operational Principles

This section outlines how diesel engines function, focusing on the combustion process that defines their operation. Understanding these principles is crucial for evaluating which diesel engine is best suited for specific applications.

- Air Intake: The engine draws in air through the intake valves. Unlike gasoline engines, diesel engines do not mix fuel with air during this phase.

- Compression: The air is compressed in the cylinder, significantly raising its temperature. Diesel engines operate at a higher compression ratio than gasoline engines, usually between 14:1 and 25:1.

- Fuel Injection: Once the air is sufficiently compressed, diesel fuel is injected directly into the combustion chamber. The high temperature of the air ignites the fuel instantly.

- Combustion: The rapid combustion of the fuel generates a significant amount of heat and pressure, pushing the piston down and creating mechanical energy.

- Exhaust: After the combustion process, exhaust gases are expelled through the exhaust valves, completing the cycle.

These operational principles not only highlight the efficiency of diesel engines but also inform decisions on performance and application suitability.

Key Engine Components

Understanding vital components of diesel engines is crucial for determining which engine best suits your needs. Each part plays a significant role in the engine’s overall performance, efficiency, and reliability. Key components include fuel injectors, turbochargers, and cooling systems, among others.

Fuel Injectors: These precision devices atomize diesel fuel, ensuring optimal combustion. The design and functionality of injectors can significantly impact fuel efficiency and power output. High-performance injectors provide better atomization, leading to more complete combustion and reduced emissions.

Turbochargers: A turbocharger increases engine power by forcing more air into the combustion chamber. This allows for more fuel to be burned, enhancing performance. Turbocharged diesel engines are known for their efficiency and power delivery, making them popular in heavy-duty applications.

Cooling Systems: Proper cooling is essential for maintaining engine performance and longevity. Diesel engines generate high temperatures, and an effective cooling system prevents overheating. Components such as radiators, water pumps, and thermostats work together to regulate engine temperature.

By focusing on these key components, you can better assess which diesel engine aligns with your specific performance and efficiency requirements.

Performance Metrics

Evaluating diesel engines requires a focus on several key performance metrics that directly influence their efficiency and effectiveness. Among these, horsepower, torque, and fuel efficiency stand out as critical indicators of an engine’s capabilities.

Horsepower measures the engine’s power output and its ability to perform work over time. Higher horsepower is generally desirable for applications requiring quick acceleration or heavy loads, such as in trucks and machinery.

Torque is the rotational force produced by the engine. It significantly affects the engine’s ability to move heavy loads, especially at lower RPMs. Engines with high torque ratings are particularly suited for towing and hauling applications, providing the necessary power to overcome resistance.

Fuel Efficiency is measured in miles per gallon (MPG) or liters per 100 kilometers (L/100 km). This metric indicates how effectively the engine converts fuel into distance traveled. Higher fuel efficiency translates to lower operating costs and reduced environmental impact, making it a crucial consideration for cost-conscious consumers.

<pBalancing these performance metrics is essential when determining which diesel engine best suits specific needs and applications. Understanding how horsepower, torque, and fuel efficiency interact can guide informed decisions for both personal and commercial use.

Application Scenarios

Diesel engines are versatile and are employed in various automotive applications, each requiring different performance characteristics. Understanding these applications helps identify which diesel engine best suits specific needs.

Trucks are one of the primary applications for diesel engines. Heavy-duty trucks, such as those used in freight transport, benefit from the torque and fuel efficiency of diesel engines, making them ideal for long-haul operations. The Cummins ISX and the Detroit Diesel DD16 are popular choices for their reliability and power.

Construction equipment also relies heavily on diesel engines. Excavators, bulldozers, and cranes require engines that produce high torque at low RPMs, providing the necessary power for demanding tasks. Engines like the Caterpillar C9 and the Perkins 804D-33T are designed specifically for heavy machinery, ensuring durability and efficiency on job sites.

Additionally, diesel engines are found in agricultural machinery. Tractors and harvesters utilize them for their longevity and ability to handle the heavy loads associated with farming operations. Models like the John Deere 4045 and the Case IH 6.7L are preferred for their robust performance in agricultural settings.

Lastly, marine applications also utilize diesel engines for their efficiency and reliability in rough conditions. Engines such as the MAN D2862 and the Volvo Penta D13 are designed for vessels requiring endurance and low fuel consumption during long voyages.

Top Diesel Engines Comparison

This section provides a detailed comparison of some of the best diesel engine models on the market today. By examining key features, performance metrics, and applications, we can determine which engine stands out in the competitive landscape.

| Engine Model | Power (hp) | Torque (lb-ft) | Fuel Economy (mpg) | Applications |

|---|---|---|---|---|

| Cummins ISB | 300-400 | 600-1,000 | 15-20 | Trucks, RVs |

| Duramax 6.6L | 445 | 910 | 15-22 | Heavy-duty trucks |

| Ford Power Stroke | 475 | 1,050 | 16-20 | Commercial vehicles |

The Cummins ISB is known for its reliability and torque, making it ideal for heavy hauling. The Duramax 6.6L excels in power and efficiency, suitable for demanding applications. Ford’s Power Stroke is recognized for its impressive torque output, which is particularly beneficial in commercial settings.

Case Studies of Best Diesel Engines

This section highlights real-world examples of vehicles equipped with some of the best diesel engines, showcasing their performance and reliability. Understanding how these engines perform in practical situations can help determine which diesel engine is best suited for specific needs.

The Ford 6.7L Power Stroke V8 is known for its impressive towing capacity and durability, making it ideal for heavy-duty trucks. Users report excellent fuel efficiency and minimal engine noise, which enhances the driving experience. The engine is also praised for its robust construction, allowing it to handle severe workloads without compromising performance.

Another notable example is the Cummins 6.7L Turbo Diesel engine used in RAM trucks. This engine excels in torque production, providing exceptional power for both towing and hauling. Owners frequently highlight its longevity and low maintenance costs, making it a popular choice among commercial operators and heavy-duty users.

Additionally, the Duramax 6.6L V8 found in Chevrolet and GMC trucks is celebrated for its smooth operation and high power output. Its advanced fuel injection technology contributes to improved emissions and fuel efficiency, appealing to environmentally conscious consumers. Performance reviews often emphasize its capability in both on-road and off-road scenarios.

Quick Summary

- Consider engine efficiency and fuel consumption for cost-effectiveness.

- Look for durability and reliability to minimize maintenance costs.

- Evaluate horsepower and torque ratings for your specific needs.

- Check for emissions compliance to meet environmental regulations.

- Research brand reputation and customer reviews for real-world performance.

- Assess warranty options and after-sales support for peace of mind.

- Compare features such as turbocharging and advanced technology integrations.

Frequently Asked Questions

Which diesel engine is considered the most reliable?

The Cummins 6.7L diesel engine is widely regarded for its reliability, especially in heavy-duty trucks. It boasts a strong track record for durability and performance, making it a popular choice among truck owners.

What factors should I consider when choosing a diesel engine?

Key factors include the engine’s horsepower and torque ratings, fuel efficiency, maintenance costs, and application suitability. It’s also important to assess the reputation and customer reviews of the manufacturer.

Are there any specific brands known for the best diesel engines?

Brands like Cummins, Duramax, and Power Stroke are well-known for producing high-quality diesel engines. Each brand has its strengths, so it’s essential to consider the specific model and its intended use.

What is the lifespan of a typical diesel engine?

A well-maintained diesel engine can last between 500,000 to 1,000,000 miles or more. Regular maintenance, including oil changes and timely repairs, significantly influences the engine’s longevity.

How do I determine the right diesel engine for my needs?

Assess your specific requirements, such as towing capacity, fuel efficiency, and the type of vehicle you need the engine for. Consulting with experts or reading user reviews can also help guide your decision.

- 10 Best Sonos Radio Stations For Music Lovers And Enthusiasts 2026 - February 5, 2026

- 10 Best Replacement Radio For 2007 Honda Accord Upgrade Your Driving Experience With Advanced Technology 2026 - February 5, 2026

- 10 Best Small CB Radio Options For Reliable Communication On The Go 2026 - February 5, 2026